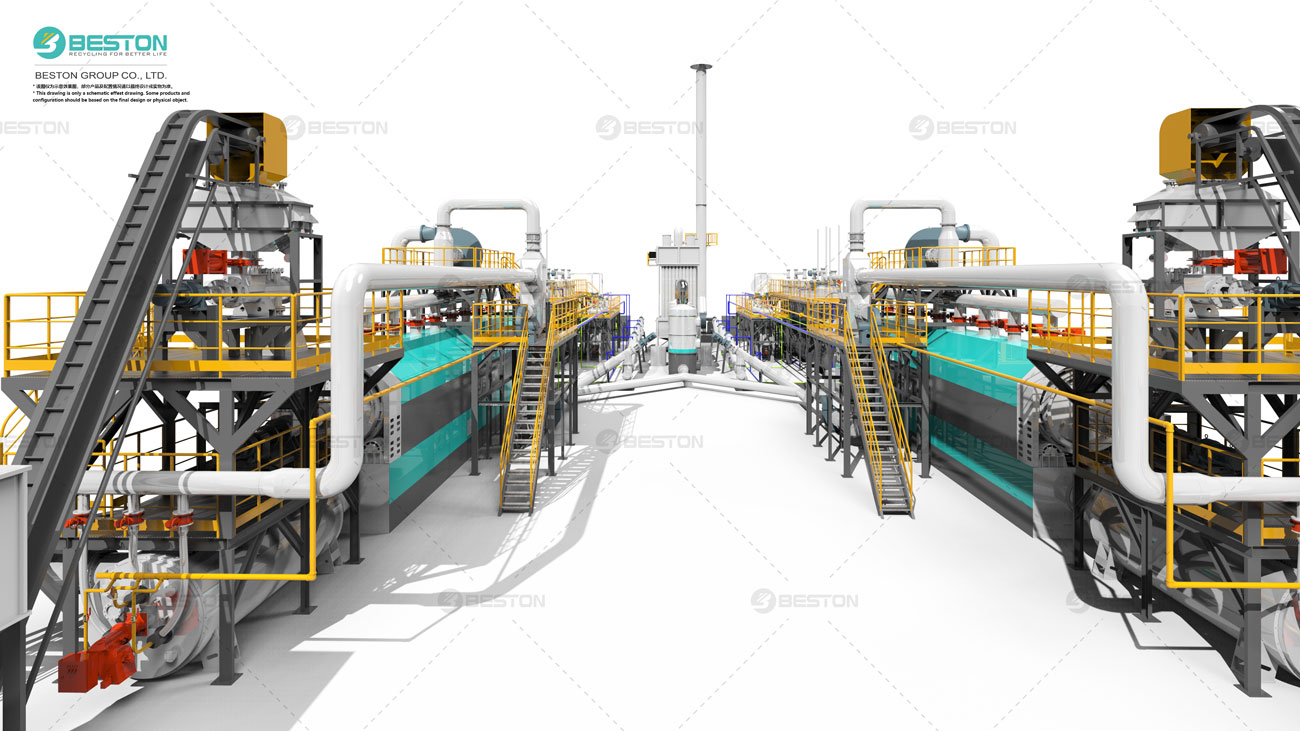

The continuous tyre pyrolysis plant represents a cutting-edge solution for converting waste tyres into valuable by-products such as pyrolysis oil, carbon black, and steel wire. The configuration of the production line in such a plant is crucial for optimizing efficiency, ensuring high-quality output, and maintaining environmental compliance. This article outlines the key components and configuration of a continuous tyre pyrolysis plant, emphasizing the technical aspects and operational benefits.

Feedstock Preparation

The first stage in the production line is the preparation of the feedstock. Waste tyres are often delivered in various sizes and forms, which must be standardized for efficient processing.

Shredding

The shredding process reduces whole tyres into smaller, uniform pieces. This step is essential for ensuring consistent feeding into the pyrolysis reactor. Industrial shredders equipped with robust blades handle the tough composition of tyres, producing chips typically around 50 mm in size. The shredding process not only facilitates easier handling but also enhances the efficiency of the pyrolysis process by providing more surface area for thermal decomposition.

Steel Wire Removal

Post-shredding, the steel wire embedded in the tyres must be extracted. This is achieved using powerful magnets and mechanical separators. Removing steel wire before pyrolysis prevents damage to the reactor and ensures smoother operation. The extracted steel wire can be collected and sold as scrap, adding an additional revenue stream.

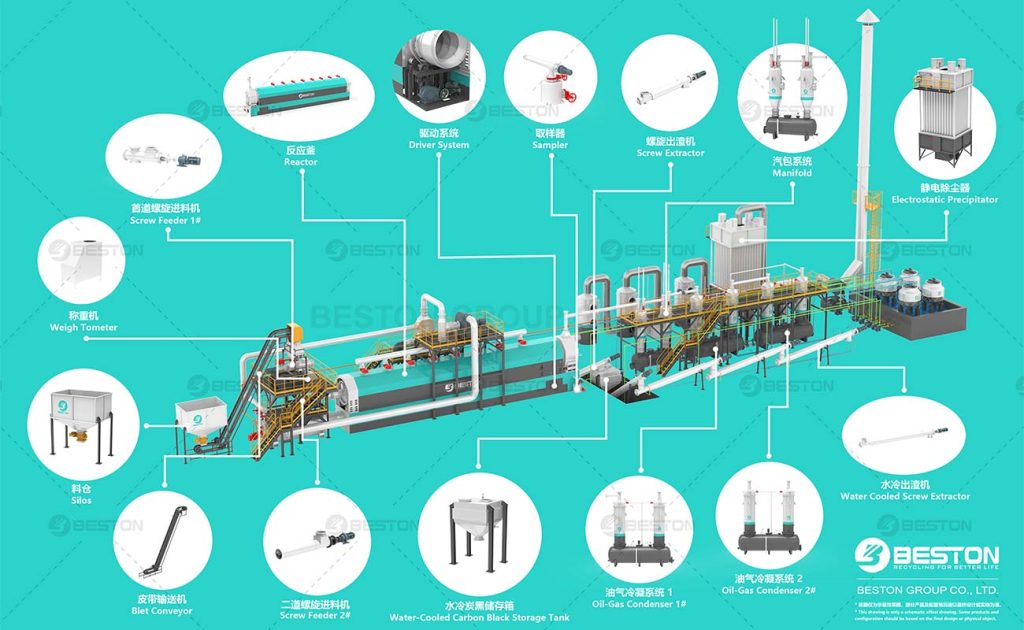

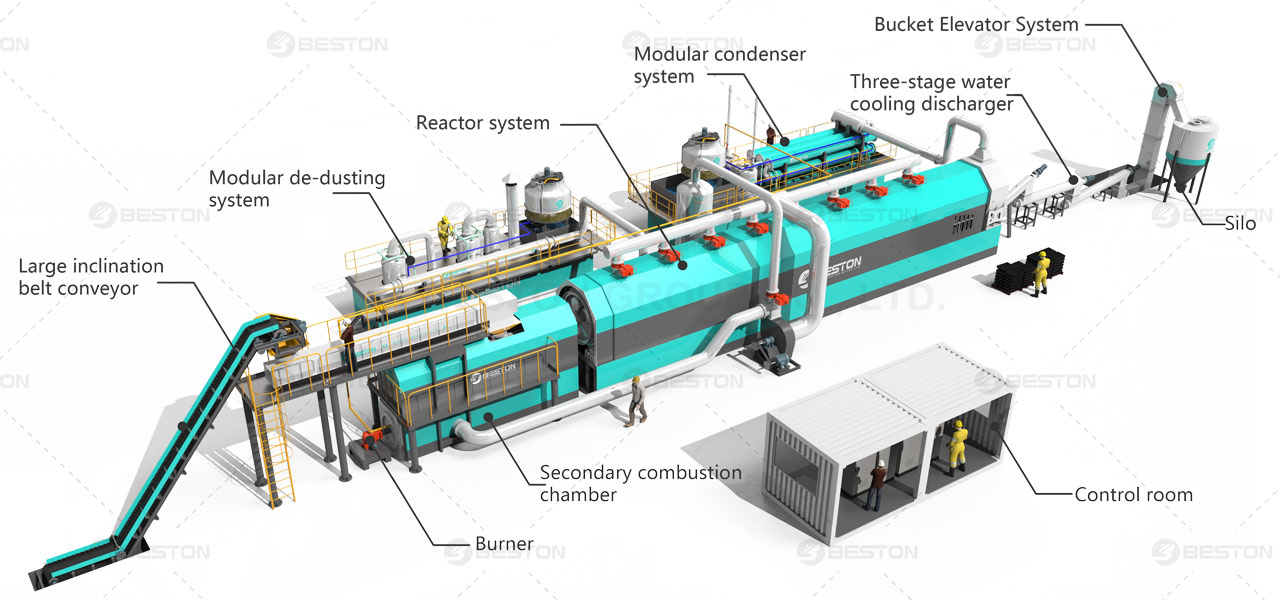

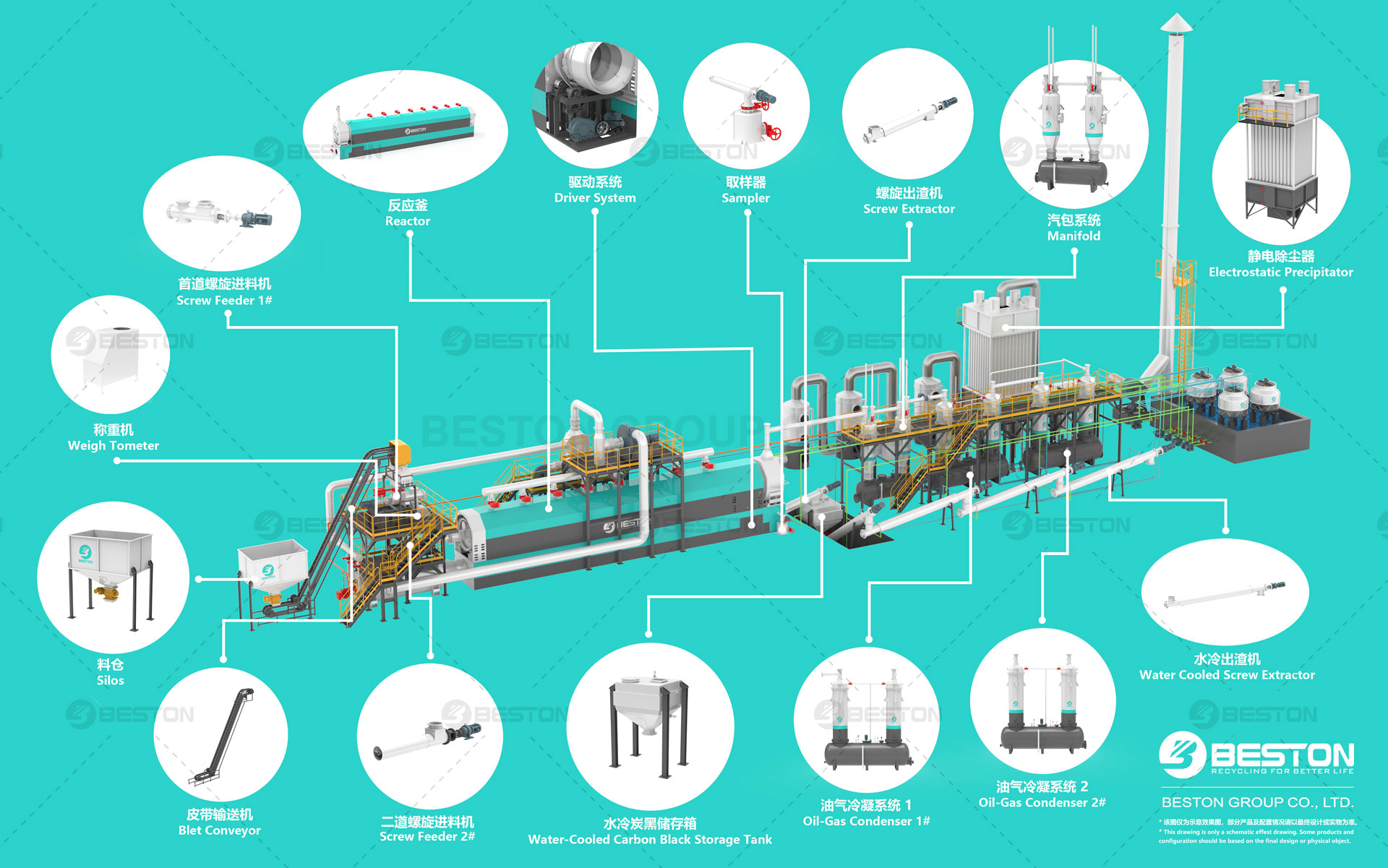

Continuous Feeding System

A continuous feeding system is critical for maintaining the uninterrupted operation of a fully continuous pyrolysis plant. This system ensures a consistent flow of shredded tyre material into the pyrolysis reactor.

Conveyor Belt

The conveyor belt transports shredded tyre chips from the feedstock preparation area to the pyrolysis reactor. Designed to handle heavy loads, the conveyor belt operates continuously, ensuring a steady supply of material. Adjustable speed controls on the conveyor belt allow for precise regulation of feedstock flow, matching the reactor’s processing capacity.

Feeder

The feeder system, typically a screw feeder, directs the tyre chips into the reactor. The screw feeder’s design prevents blockages and ensures even distribution of material within the reactor. Continuous operation is facilitated by the feeder’s robust construction and reliable performance.

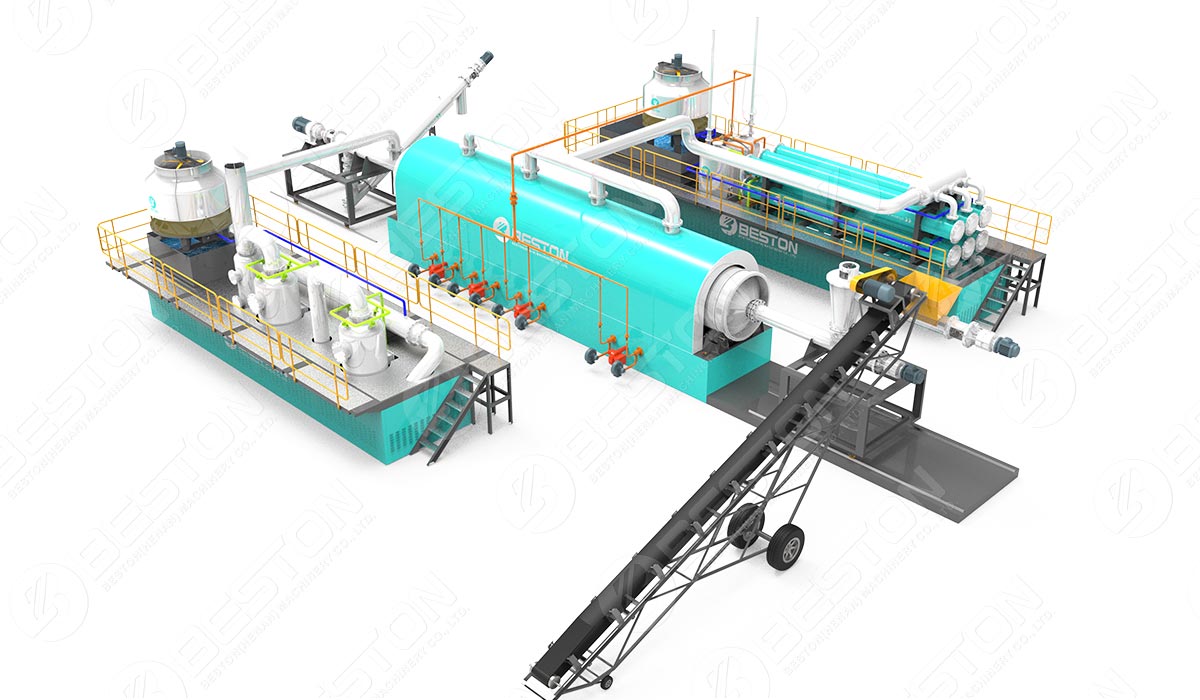

Pyrolysis Reactor

The heart of the continuous tyre pyrolysis plant is the pyrolysis reactor. This component is where thermal decomposition of the tyre material occurs, breaking down the long-chain polymers into smaller molecules.

Reactor Design

Continuous pyrolysis reactors are often designed as rotary kilns or fluidized bed reactors. Rotary kilns are cylindrical and rotate to ensure uniform heating of the tyre material. Fluidized bed reactors, on the other hand, use a bed of inert material that keeps the tyre particles suspended, promoting even heat distribution and efficient thermal decomposition.

Heating System

The heating system maintains the reactor at the optimal temperature for pyrolysis, typically between 350°C and 500°C. Indirect heating methods, such as the use of a furnace or hot gas, are preferred to prevent combustion. The heating system is carefully controlled to ensure steady temperatures, which is vital for the consistent quality of the pyrolysis products.

Temperature and Pressure Control

Maintaining precise control over temperature and pressure within the reactor is crucial for efficient pyrolysis. Advanced control systems equipped with sensors monitor these parameters in real-time, allowing for immediate adjustments to maintain optimal conditions. This ensures high conversion rates and consistent product quality.

Gas and Oil Separation

The pyrolysis process generates a mixture of gases and liquid oil, which must be separated and processed further. Beston Group Co., Ltd.‘s advanced oil-gas condensation system helps customers obtain higher quality tire pyrolysis oil.

Condensation System

The hot gases exiting the reactor pass through a series of condensers, where they are cooled and condensed into liquid pyrolysis oil. Efficient condensation systems maximize oil recovery and ensure high purity. The design of the condensers, often involving multiple stages, enhances the separation process and improves overall efficiency.

Gas Collection

Non-condensable gases, such as methane, hydrogen, and carbon monoxide, are collected separately. These gases can be utilized as a fuel source for the heating system, making the process more energy-efficient and reducing reliance on external energy sources. Excess gas can be stored or flared off in compliance with environmental regulations.

Carbon Black Collection

Carbon black, a valuable by-product of tyre pyrolysis, is collected from the reactor.

Cyclone Separator

A cyclone separator is used to extract carbon black from the gas stream. This equipment relies on centrifugal forces to separate fine carbon black particles from the gases. The collected carbon black is then transported to storage bins for further processing or sale.

Bag Filter

For finer filtration, bag filters may be used to capture any remaining carbon black particles. These filters ensure that the emitted gases are clean and compliant with environmental standards. The captured carbon black is periodically removed and added to the main collection.

Cooling System

Post-pyrolysis, the remaining solid residue and gases must be cooled before further handling.

Water Cooling

Water cooling systems are often employed to reduce the temperature of the solid residues and gases. The cooled residues are easier to handle and safer to transport. Water jackets or spray systems are commonly used for this purpose, ensuring efficient heat exchange and rapid cooling.

Air Cooling

In some configurations, air cooling systems may be used as an alternative or supplement to water cooling. Air coolers are particularly useful for handling non-condensable gases, reducing their temperature before they enter further processing stages or storage.

Control System

A sophisticated control system is integral to the operation of a continuous tyre pyrolysis system. This system monitors and regulates all aspects of the production line, ensuring optimal performance and safety.

Programmable Logic Controller (PLC)

A PLC system automates the control of the plant, executing complex algorithms to maintain ideal operating conditions. The PLC interfaces with sensors and actuators throughout the production line, providing real-time data and enabling precise control.

Human-Machine Interface (HMI)

The HMI provides operators with a user-friendly interface to monitor and control the plant. This interface displays real-time data, alarms, and system status, allowing operators to make informed decisions and respond quickly to any issues. Advanced HMIs also offer data logging and reporting features, aiding in performance analysis and continuous improvement.

Environmental Control

Ensuring that the continuous tyre pyrolysis plant operates within environmental regulations is essential for sustainable and compliant operation.

Emission Control

Emission control systems, including scrubbers and filters, remove harmful pollutants from the exhaust gases. These systems ensure that the plant meets stringent environmental standards and minimizes its impact on the surrounding environment. Regular monitoring and maintenance of emission control equipment are critical for maintaining compliance.

Waste Management

Proper management of solid and liquid waste is vital for environmental sustainability. The residues from the pyrolysis process, such as ash and unreacted materials, are collected and disposed of according to regulatory guidelines. Effluent treatment systems are used to treat any wastewater generated during the process, ensuring that it is safe for discharge or reuse.

Conclusion

The configuration of a continuous tyre pyrolysis plant production line is a complex and multi-faceted process. From feedstock preparation to final product collection, each component plays a crucial role in ensuring efficient, sustainable, and profitable operation. By optimizing each stage of the production line, operators can maximize output, reduce costs, and minimize environmental impact, making continuous tyre pyrolysis a viable and advantageous solution for waste tyre management.