When starting a waste plastic pyrolysis business, the cost of the pyrolysis machines is usually the first thing you should consider. This is because it’s the most financially demanding aspect of the project. More so, it is the core of the business and determines how successful a business venture will be. Furthermore, there are other factors that will need to be taken into account in a large-scale project such as this.

The first investment will almost certainly be dominated by the pyrolysis plant cost. The first prevalent forms of pyrolysis equipment on the market are intermittent pyrolysis plants, which cost between $30,000 and $79,000. The second is the continuous pyrolysis plants, which cost between $280,000 and $650,000. Of course, the cost is only an estimate, and it varies depending on the pyrolysis plant’s capacity

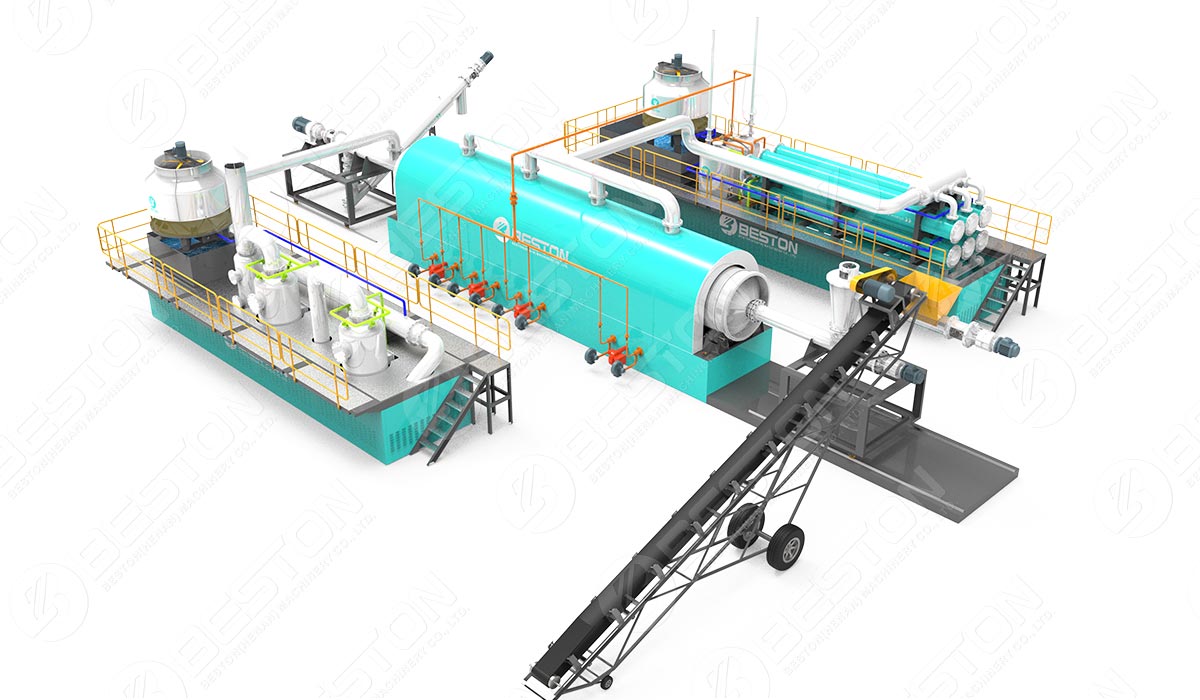

Pyrolysis Plant Cost

After-purchase Costs

Besides the purchase cost, you will pay certain follow-up service fees, such as installation, repair, and maintenance, after purchasing a waste plastic pyrolysis plant. Plant site expenses, fuel prices, utility costs, and personnel costs are among the other costs.

These expenses could be distressing for you. When a waste plastic pyrolysis plant for sale is run, however, the end output is fuel oil, carbon black, and flammable gas. You will see a big return if the finished product is good enough and the factory functions efficiently.

Justification of Incurring the Pyrolysis Plant Costs.

The Plant Provides a Sealed System for Slag Discharge and Feeding

The sealed feeding system can help reduce raw material waste while also ensuring safety and environmental protection. Because the slag discharging system is likewise enclosed and high-temperature resistant, you do not have to cool the reactor before draining the carbon black. Instead, it can be released at a higher temperature directly, saving time on reactor cooling.

Comes With an Efficient Gas Reuse System

After de-dusting and desulfurization, the combustible gas created during the combustion process can be used to heat the reactor. This helps to reduce fuel expenditures significantly. Of course, the flammable gas can also be collected in an airbag. To ensure the safety of the pyrolysis process, the gas bladder should be located away from the combustion chamber. More information on tyre pyrolysis plant UK here.

BLL-20 Installed in Romania

High-Quality Material for the Pyrolysis Reactor

The pyrolysis reactor is made out of robust and high-temperature resistant materials, while the housing is made out of refractory materials. Consequently, the pyrolysis reactor’s service life will be extended, and the customer will save a lot of cash. This is because they will not have to buy a new reactor.

Wind Up

The impacts of trash vary greatly, and they are impacted by the components or chemicals found in the garbage, as well as how they are treated. Hazardous waste generation and handling can pollute land, air, and water, posing a threat to human health and the environment. As a result, finding new ways to manage waste, such as through the utilization of a pyrolysis plant, is critical.

The use of high temperatures degrades harmful components and microorganisms, which is one of the benefits of pyrolysis. The increased operating temperature also causes a drop in water volume. More importantly, you can limit the supply of external fuel by utilizing the generated gases as fuel. See pyrolysis plant in Nigeria here.