The world is at a crossroads when it comes to addressing environmental challenges. Climate change, resource depletion, and pollution have necessitated a paradigm shift towards more sustainable practices. One significant innovation on the horizon is the development of new pyrolysis equipment, which promises to revolutionize waste management, energy production, and resource conservation. This article explores the innovations and emerging trends in new pyrolysis equipment, shedding light on its potential to shape a greener future.

The Pyrolysis Revolution

Pyrolysis, a thermal decomposition process in the absence of oxygen, has been employed for centuries, primarily in the production of charcoal. However, modern advancements have transformed this ancient technique into a promising pyrolysis plant project for addressing contemporary environmental issues.

1. Biomass and Waste Conversion

Traditionally, pyrolysis was used for carbon-rich materials, but innovation has extended its applications to biomass and various types of waste. This development is crucial in addressing the ever-growing problem of municipal and industrial waste disposal. New pyrolysis equipment can convert these wastes into valuable products like biochar, bio-oil, and syngas, reducing landfill dependence and generating alternative energy sources.

2. Sustainable Energy Generation

One of the most exciting trends in new pyrolysis equipment is its potential to generate sustainable energy. By converting organic materials into biofuels and bioenergy, pyrolysis can contribute significantly to reducing our reliance on fossil fuels. Emerging technologies are making it increasingly efficient to produce biofuels like biodiesel and green hydrogen, which have lower greenhouse gas emissions and a smaller environmental footprint.

3. Circular Economy Integration

Tyre pyrolysis plant is at the forefront of the circular economy movement. It promotes recycling and resource recovery by converting waste materials into valuable resources. By reusing plastics, rubber, and other waste products, pyrolysis contributes to the creation of a closed-loop system where materials are continuously recycled, minimizing the need for virgin resources.

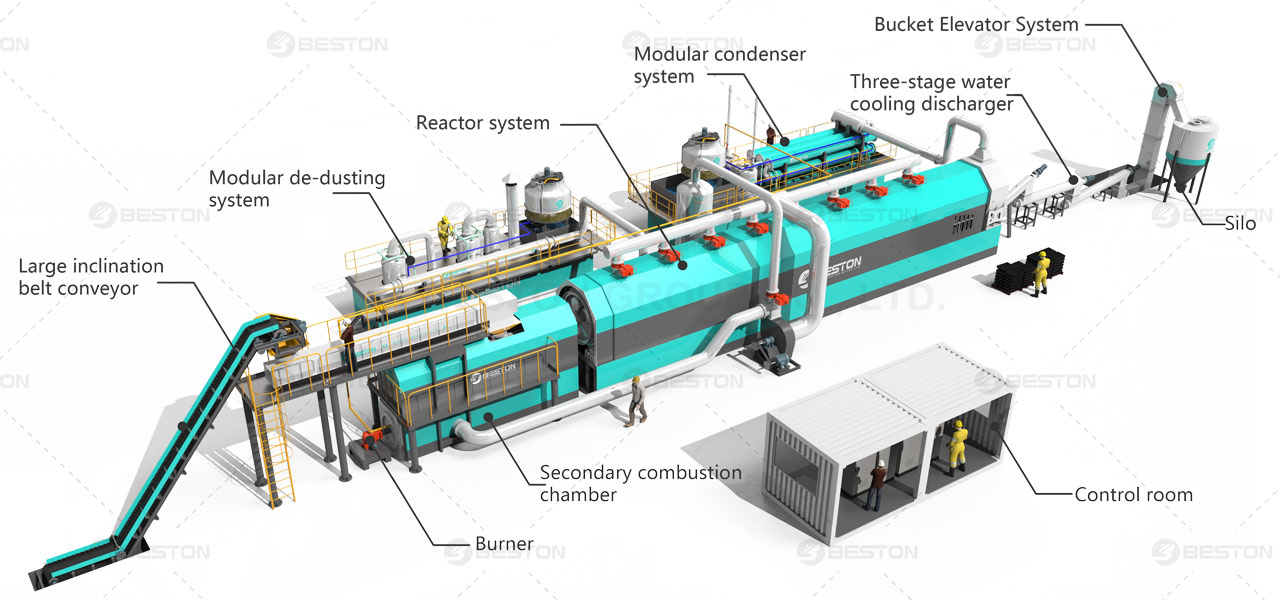

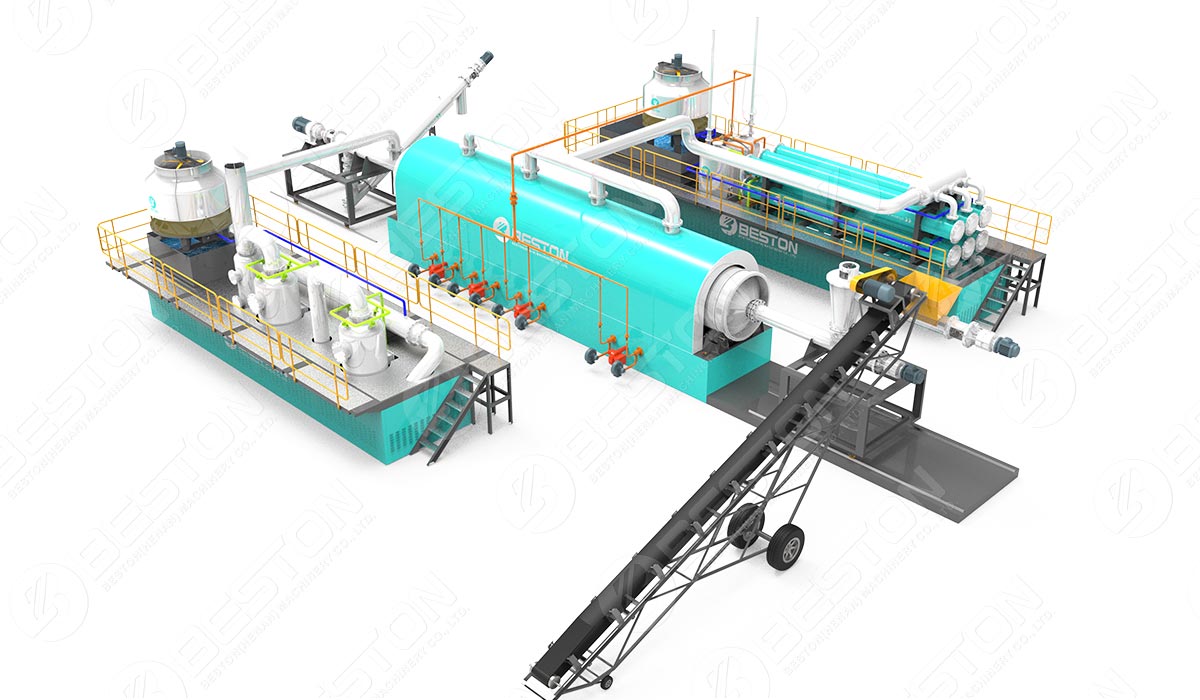

3D Layout of Beston Pyrolysis Plant

Innovations in Pyrolysis Technology

The journey toward sustainable pyrolysis has seen significant technological innovations that are shaping the equipment of the future.

1. Advanced Reactor Designs

New pyrolysis equipment features advanced reactor designs that enhance the efficiency of the pyrolysis process. Fluidized bed reactors, rotary kilns, and microwave pyrolysis systems are some examples. These innovations enable better temperature control, faster reaction times, and improved product yields.

2. Catalytic Pyrolysis

Catalytic pyrolysis is another breakthrough in plastic pyrolysis plant. By using catalysts, this process can achieve higher conversion rates and produce cleaner and more valuable products. Catalysts like zeolites and metal oxides are being extensively researched for their potential in upgrading pyrolysis products.

3. Integration of Artificial Intelligence

Artificial intelligence (AI) is being integrated into pyrolysis equipment to optimize process control and product quality. AI algorithms can analyze data in real-time, adjusting operating parameters to maximize efficiency and minimize emissions. This smart technology ensures consistent and environmentally friendly production.

Environmental Benefits

Pyrolysis Plant Cost

New pyrolysis equipment offers several environmental benefits that are critical in the fight against climate change and pollution.

1. Reduced Greenhouse Gas Emissions

The production of biofuels through pyrolysis results in significantly lower greenhouse gas emissions compared to fossil fuels. This reduction in emissions helps mitigate climate change and improve air quality.

2. Waste Reduction

By converting waste materials into valuable products, pyrolysis reduces the burden on landfills and incineration facilities. This not only conserves valuable land but also minimizes harmful emissions from waste disposal.

3. Resource Conservation

Pyrolysis contributes to resource conservation by enabling the reuse of materials like plastics and rubber. This conserves energy and raw materials that would otherwise be required for the production of new products.

Challenges and Future Directions

While new pyrolysis equipment holds immense promise, it also faces certain challenges. These include scaling up production, cost competitiveness with conventional processes, and ensuring environmental sustainability throughout the entire lifecycle.

To address these challenges, ongoing research and development efforts are crucial. Public and private sector collaboration is essential to drive innovation and create an enabling environment for the adoption of pyrolysis technology on a global scale. You can visit Beston Group to know more information.