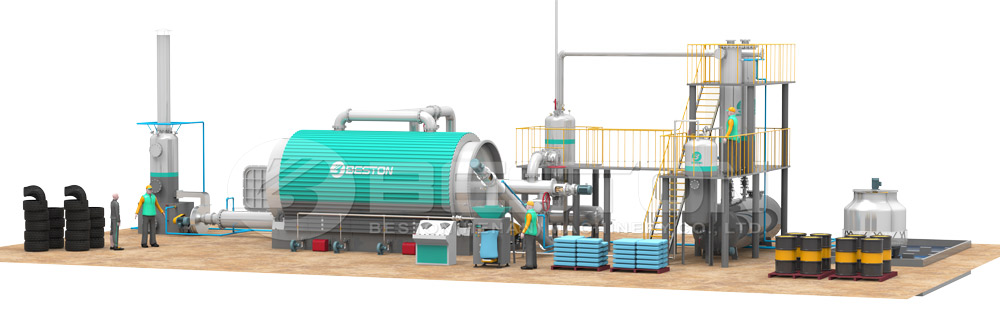

Production of paper egg crates is a lucrative venture considering the increasing demand for eggs. The market is vast both in industries making relevant products and locally from the communities. Advancements in technology have paved the way for different versions of pulp egg tray machine to make these products. The egg tray making machine comes in either manual, semi-automatic, and fully automatic models. However, a considerable number of manufacturers can pose a challenge when you are trying to make settlements. It is vital to take into account the following tips to ensure you get the best device.

Egg Tray Making Machine in the Philippines

Manufacturing Capacity

The first and most crucial thing to check when evaluating these machines is the production level. The devices available on sale from different sellers have different functionality levels. Production capacity gets determined by the mechanism of operation, either manual or automatic. Most people tend to assume that the bigger the device, the higher the output. However, you need to evaluate the machine at an in-depth level to ascertain its capability. The manual egg tray making machine will be cheaper. While the fully automatic egg tray machine price will be higher. The size of your market will play a massive role in guiding you further. If your company is a start-up and you have a little need, then a machine with an average production rate will work correctly. In big companies with many clients, an egg crate making machine with high quality should work efficiently. The accurate margin has to be between 4000 to 6000 pieces per hour.

Mode Of Operation

There are three different modes of operations employed by the egg crate making machine. The first and most powerful type is the automatic brand. It is the most common and efficient due to its high rate of production. Working with it requires limited investment regarding employees as it requires minimal manual input. It works suitably in large industries with a huge demand for the end product. The second version is the semi-automatic model. It works in a more or less manner to the first option. However, the production rate is much lower. Some parts require additional input to ensure there is a smooth flow of operations. The final design is the manual models. It is the cheapest of them all in terms of purchasing costs. However, you have to further part with more money employing staff to help in the production. In most cases, the drying stage, a critical part of the exhibition, relies on natural drying, which is also time-consuming. Before you opt for this model, assess the market to ensure it complements the machine’s capabilities.

Egg Tray Making Machine in Dominica

Egg Carton Machine Cost

Just like any other commodity in the market, whatever you spend is what you get. The same applies to egg crate making machines. Do not get attracted to lower prices as it could be a gateway to disappointments. Look beyond the requested figure and further into the primary aspects like durability and type of manufacturer. Try to strike a balance between cost and value.

As seen above, choosing an egg crate making machine can be a smooth and short process of you adhere to the above tips. Do not be hasty; instead, take time to conduct research and make comparisons. If you need an egg tray making machine project report, please check the link here: https://bestoneggtraymachine.com/egg-tray-manufacturing-business-plan/.