Are you thinking about getting a new stirrup bender machine that is going to fit in nicely with what you have going on as of right now? You are going to have to think about what the CNC coiled rod stirrup bending machine can bring to the party because it is a powerhouse and one you will enjoy.

It is best to take a look at the value you are going to receive from this monster of a CNC bending machine for sale and why people are going for this first over anything else.

1) Impressive Features

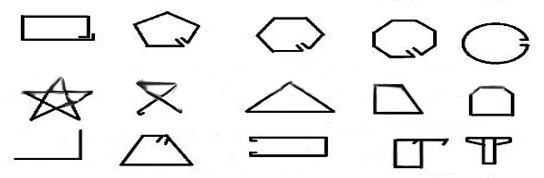

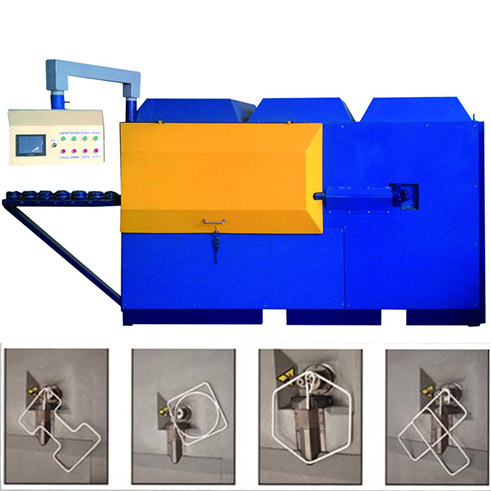

The features of the CNC coiled rod stirrup bending machine all come together to work ideal for those who are aiming to get the bending equipment. You will have features where all of it is automated from the moment you have put in the dimensions. It can take the steel and churn it out the way you want it to be provided.

The stirrup that is going to be bent will come out in a manner where you are able to use it to your advantage in the long-term.

This is the key.

2) Simple To Use For Bending

Operators don’t want to fiddle around for long when it comes to the machine they are using. You are thinking about the dimensions and other factors, so the operation component should be easy. This is why the CNC coiled rod stirrup bending machine is such a great option. More information about this machine, please come to this page: http://ellsenbendingmachine.com/cnc-wire-bending-machine/.

You can go through the controls and automate everything so that you are not as involved in what is going on.

You can just sit back and know the machine is going to do the work for you. It is going to look at what you have put in when it comes to the dimensions and precisely bend the steel.

3) Immaculate Finishing

The finishing matters because you are not just bending the reinforcing bars, you are looking to get them to work well with what you have going on. There are many examples where the stirrups are not as clean as they should be, and this is where finishing starts to lack.

You cannot let this happen because you are paying for the machine not only to be accurate which is a must, but to also make sure it is helping with the finishing of the stirrups as well after bending them. This is just as important.

Look to get the CNC coiled rod stirrup bending machine as soon as you can because it does not get better than a machine such as this. You are receiving one of those high-quality machines that will take the stirrups and turn them into what you want effective immediately.

You will be able to focus on the rest of your project and know the dead loads and other concerns that you might have are going to be packed up with the help of your bent stirrups automatically. This is the value of getting the bender machine to help you out.

If you have bending business to deal with, welcome to this website ellsenbendingmachine.com. Ellsen bending machine manufacturer provides different types of benders for you to choose form. Besides, Ellsen also provides custom-made machines.