Turning wood into charcoal is one of the most efficient methods of disposing off wood waste and achieving resource recycling. In the modern age, this is done using a machine known as a wood charcoal making machine(hornos metalicos para hacer carbon) using through a process known as carbonization. This machine has proven to be highly useful for entrepreneurs looking to dip their toes into the charcoal making business. It allows you to properly dispose off your wood waste while earning a profit. What’s more, it has a profit margin since the raw material used to produce the biochar is cheap and easily available.

Hornos metálicos para hacer carbón

Wood chips charcoal making machine carbonization process

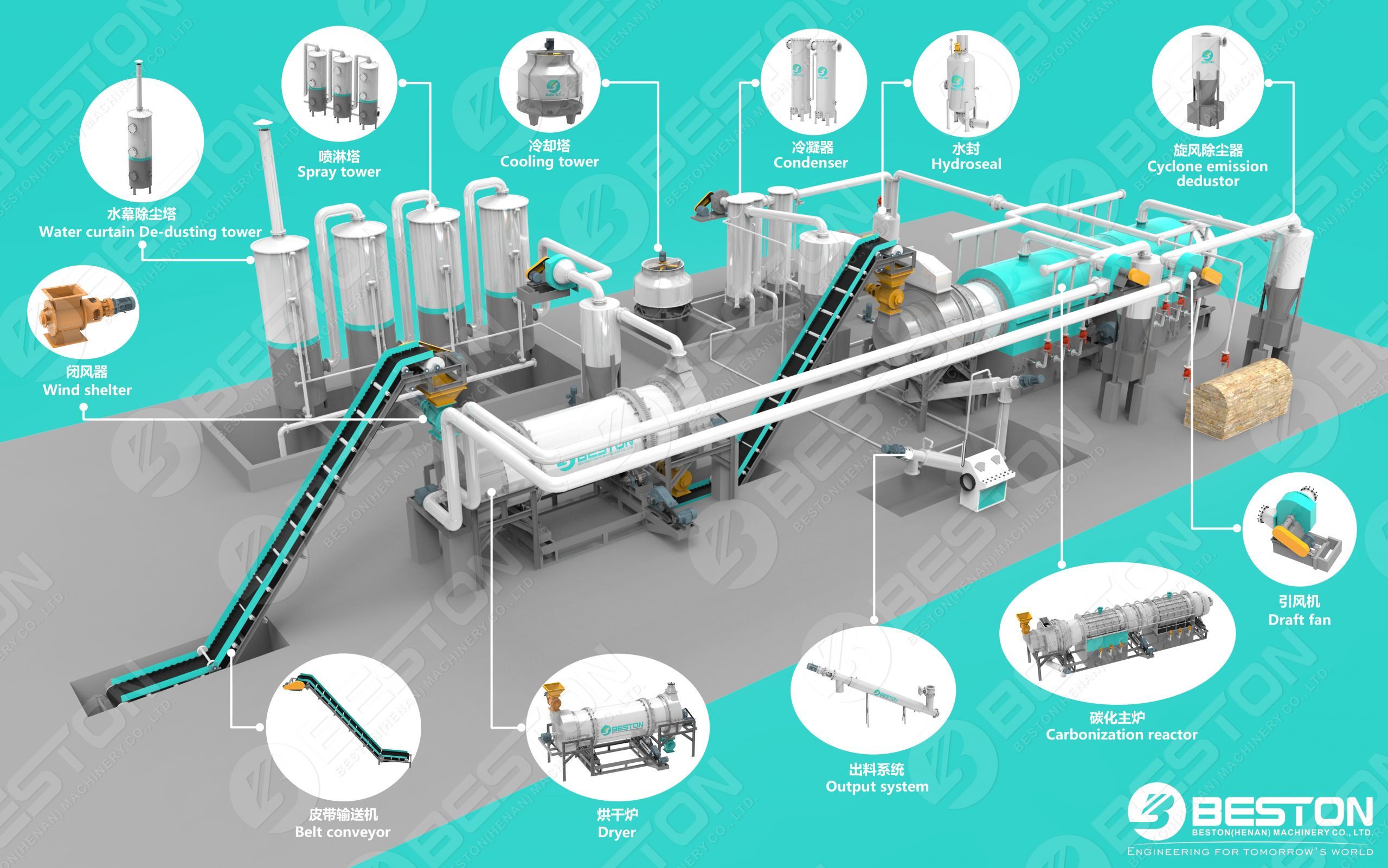

The wood charcoal making machine(https://www.bestoneco.com/maquina-para-hacer-carbon-vegetal/) comes with different components, all of which play a crucial role in turning the raw materials into the various useful end-products. The process of wood carbonization begins with the pre-treatment of the raw materials which happens in the dryer and crusher. The dryer is responsible for removing all the residual moisture in the wood material while the crusher is responsible for cutting the wood into tiny wood chips. It is important to crush the wood materials into tiny pieces to ensure uniform heating. Once this is done, the raw material move to the heating furnace where the treated raw materials are heated under high temperature (usually above 400 degrees celsius) in an oxygen-free atmosphere – a process known as pyrolysis. Once the temperature reaches around the 400 degrees celsius mark, biochar is produced. In the reactor, biogas will also be produced.

Wood charcoal making machine biogas production and use

As stated above, combustible gas is also during the carbonization process(máquina de carbonización montado sobre patines). In the beginning of the process, fuel sources such as wood, natural gas, and coal are used to pre-heat the wood carbonization furnace. This happens for around 30 minutes and once the required temperature is achieved, combustible gas is produced. Fortunately, this gas is highly useful as it can be recycled or used for a wide range of other purposes. Once it is generated, it is passed through the spray dedusting system where it is purified and collected or used to heat the heat furnace or even the dryer. This means that you can gain significant savings in terms of fuel costs.

Uses of end-products of the wood charcoal making machine process

The wood charcoal making machine is beneficial in more ways than one. The investor can find great use for the end products of the wood charcoal making machine process, including biochar, tar, and wood vinegar. Charcoal is widely used a source of fuel for both domestic and industrial purposes. It is also attached to heavy metals to improve the quality of soil. It is also used in the making of clay construction bricks. Wood vinegar and tar are widely used in the ship building industry(Compañía Bestoneco), as well as ingredients in paints. They are also used as raw materials in the chemical and medicine fields. They also used in agriculture as plant nutrition.

As you can see, there are plenty of benefits to gain from investing from a wood chip charcoal making machine.