Introduction

Pyrolysis, a sophisticated process in waste management, offers a transformative solution to environmental challenges. Understanding the intricacies of the running costs associated with a pyrolysis plant is imperative for the sustainable and efficient operation of such facilities.

Feedstock Procurement

Types of Feedstock

In the realm of pyrolysis plant cost, feedstock diversity is not just a variable but a crucial determinant of operational costs. Plastics, biomass, and rubber present distinct challenges and costs. Unraveling the nuances of different feedstock types allows for strategic decisions in minimizing overall costs.

Factors Influencing Feedstock Costs

The procurement of feedstock involves navigating a complex web of factors. From transportation logistics to the quality of the material, each element contributes to the final cost. Understanding and dissecting these factors is paramount in formulating a cost-effective strategy for feedstock acquisition.

Energy Consumption Optimization

Pyrolysis Process Energy Demands

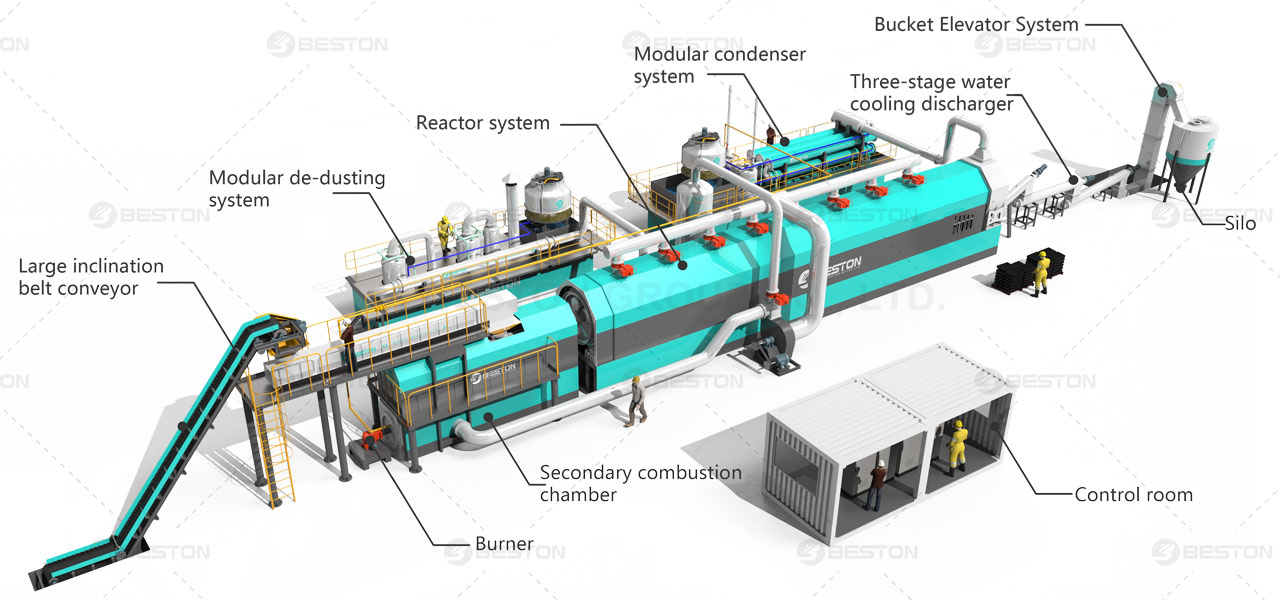

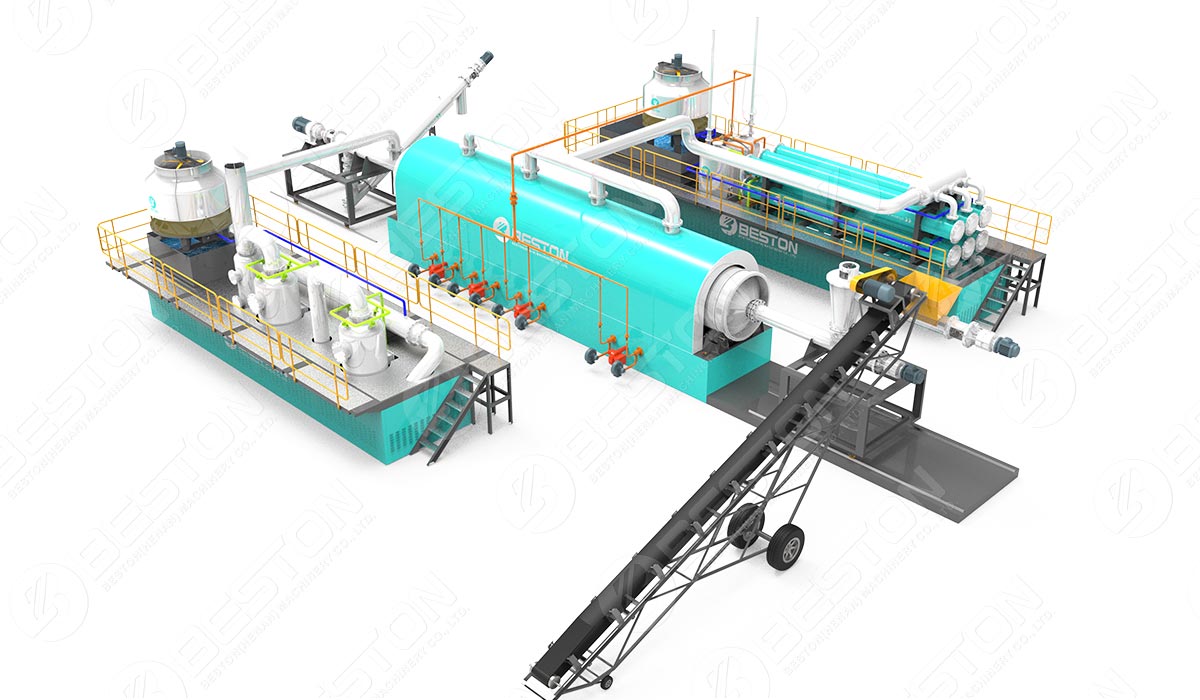

Within the heart of a pyrolysis plant lies the energy-intensive pyrolysis process. Analyzing the specific energy demands at different stages provides opportunities for optimization. The judicious use of heat and the implementation of energy-efficient technologies become focal points in the quest for operational cost reduction.

Strategies for Energy Efficiency

Efficiency in energy consumption is not just a cost-cutting measure but a strategic imperative. From heat recovery systems to advanced control mechanisms, the arsenal of strategies available to minimize energy consumption is diverse. Each strategy contributes to the overarching goal of ensuring that energy costs are proportionate to the output.

Maintenance and Equipment Longevity

Regular Maintenance Practices

The machinery in a pyrolysis plant is a symphony of intricate components. Regular maintenance practices are not merely preventive but instrumental in extending the lifespan of critical equipment. This proactive approach not only reduces the frequency of breakdowns but also curtails the financial impact of equipment depreciation.

Mitigating Equipment Depreciation Impact

Equipment depreciation is an inherent aspect of any industrial operation. Yet, the impact can be mitigated through strategic maintenance and upgrade plans. By understanding the correlation between maintenance frequency and equipment depreciation, a pyrolysis plant can navigate the fine line between operational efficiency and financial prudence.

Skilled Labor and Automation

Role of Skilled Operators

The human element in operating a pyrolysis plant is irreplaceable. Skilled operators are not just overseers; they are custodians of the optimal conditions required for the pyrolysis process. Investing in training programs for these crucial personnel is an investment in operational efficiency and long-term cost-effectiveness.

Integration of Automation for Cost Reduction

Automation emerges as a powerful ally in the quest for cost reduction, especially in a continuous pyrolysis plant. Beyond mere efficiency gains, automation reduces reliance on manual labor, presenting a dual benefit of operational streamlining and labor cost savings. The initial investment in automation technology unfolds as a prudent decision in the long-term financial landscape.

Regulatory Compliance

Environmental Standards and Permits

The regulatory landscape for pyrolysis plants is multifaceted. Navigating the labyrinth of environmental standards and obtaining permits incur costs that are non-negotiable. An in-depth understanding of these compliance measures is essential for both legal adherence and prudent financial planning.

Waste Disposal and Emissions Control

Environmental responsibility extends beyond legal requirements. Implementing effective waste disposal methods and cutting-edge emissions control technologies not only meets regulatory standards but also positions the pyrolysis plant as a conscientious contributor to environmental preservation. The costs incurred here are investments in a sustainable future.

Technological Upgrades and Innovation

Continuous Technological Advancement

The pyrolysis landscape is dynamic, with continuous technological advancements shaping its trajectory. Remaining at the forefront of these innovations is not just a competitive advantage but a necessity. Upgrading equipment and processes for higher efficiency is a strategic move that requires a keen eye on industry trends and a commitment to staying technologically relevant.

Evaluating Return on Investment for Upgrades

In the realm of technological upgrades, the bottom line is a critical metric. Evaluating the return on investment (ROI) for each upgrade ensures that the costs incurred translate into tangible benefits. Whether through increased efficiency, reduced operational costs, or expanded capabilities, every upgrade should be a calculated step toward a more sustainable and economically viable operation. If you want a more cost-effective operation plan, please consult Beston Group, an expert in solid waste recycling.

Economies of Scale and Operational Efficiency

Impact of Scale on Running Costs

The scale of operation is not just a metric; it’s a lever that can influence running costs. Larger production capacities often lead to economies of scale, where the cost per unit of output decreases with increased production. This shift in scale can significantly impact the financial landscape, presenting both opportunities and challenges.

Challenges and Considerations in Scaling Up

Scaling up is not without its challenges. Logistical complexities, increased regulatory scrutiny, and the need for substantial initial investments are hurdles that must be navigated. Understanding the intricacies of scaling up is crucial for a pyrolysis plant aiming to maximize its operational efficiency while managing the associated costs.

In conclusion, the running cost of a pyrolysis plant is a mosaic of interconnected elements. From feedstock procurement to scaling up operations, each facet requires meticulous attention. Navigating this intricate landscape with a strategic and technical mindset is not just a financial imperative but a commitment to the sustainable future of waste management through pyrolysis.