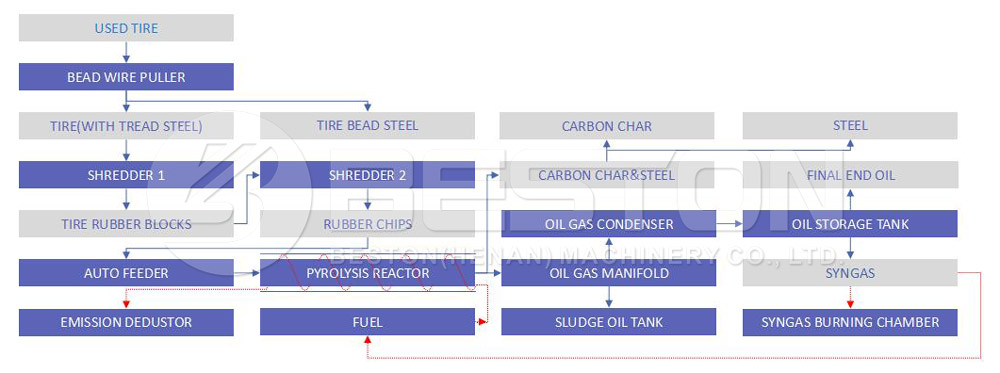

The tire recycling plant is one of the best pieces of equipment you can invest in. This plant uses pyrolysis technology to take waste tires and turn them into something useful. The tire pyrolysis recycling equipment is easy to operate to turn old tires into oil and this oil is high-quality and easy to process and use. The oil can be used right away and it can also be processed into gasoline and used to run machinery. So you can make great profits from tyre pyrolysis recycling business. More about the profits analysis can be found: https://ecobeston.com/pyrolysis-plant-profit-analysis/.

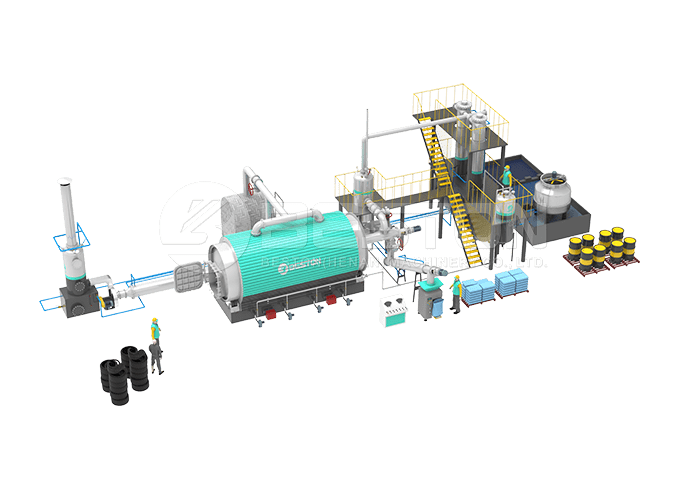

Tire Recycling Plant in Indonesia

Any type of old tires can be used which means you can take the old tires out of the landfill and use them however you need them. The tires are going to be taken out of the landfill which means that they won’t be polluting the environment. The machine takes the tires and heats them up to a very high temperature where they turn into oil.

The pyrolysis process is safe and it is also reliable. The machine is easy to set up and use and you can expect to get a lot of help from the manufacturer. The qualified pyrolysis plant manufacturer, such as Beston Machinery, can help you choose the machine and they will also ensure that you end up with the right setup. They will install the machine and set it up for you so you know you have it running properly. They even provide training so you don’t have to worry about problems.

Waste Tyre Recycling Plant in Turkey

You get help with all of your technical issues as well so you don’t have to worry about problems. The tire recycling plant is very versatile and it helps you take care of all of your needs so you don’t have to worry about problems. The machine makes tons of oil fast so it can make a lot of money quickly as well.

The tyre recycling machine is comfortable to operate. The heating chamber has two layers so you don’t have to worry about workers feeling uncomfortable when they are working with the machine. The machine is easy to run and the manufacturer provides training so you have an easy time figuring out how to use the machine. Your workers will learn how to use the machine fast and they will be ready to start running it so you can get more done. More models can be found: https://ecobeston.com/tyre-recycling-plant/.

The tyre recycling machine makes tons of oil fast and it takes all of the old tires out of the landfill so you don’t have to worry about harming the environment. The machine is affordable and it comes in multiple models so you can easily find the model that is going to be the best fit for your needs when you work with the manufacturer. They will help you find the machine that is the best fit and that helps you produce all of the oil you need to produce.

The tire recycling machine is good for the environment and it also makes you money. The Beston pyrolysis plant is guaranteed to last for a long time and it is also made with the best materials. The machine is affordable and it ensures that you get a lot of things done.