Egg tray making machines are utilized to make paper egg trays from reused squander paper and water. Its creation is comprised of three principle stages which incorporate pulping, shaping and drying. The pulping framework blends the waste paper and water to the right focus. The mash is then moved to the shaping framework where the egg trays are made. At long last, the drying framework dries the egg trays since regardless it contains water. The yield of this machine is measured by some trays every hour and is significantly reliant on the size and nature of the machine. The operation of the machine can either be programmed or self-loader. These days, egg tray machine is turning out to be increasingly well known. The egg tray machine price of our factory is reasonable.

The egg tray making machine price subject to the furthest reaches of the PC. There is manual, self-loader and completely modified paper egg tray machine. The yield can accomplish 1000-7500 pieces a hour. The particular sorts of the machines have different advancement and assorted contraptions. For example, the modified egg tray making machine has customized era process and high proficiency. So it has a higher price than the manual and self-loader machine. You should pick the machine as demonstrated by your capacity demand and wander spending arrangement.

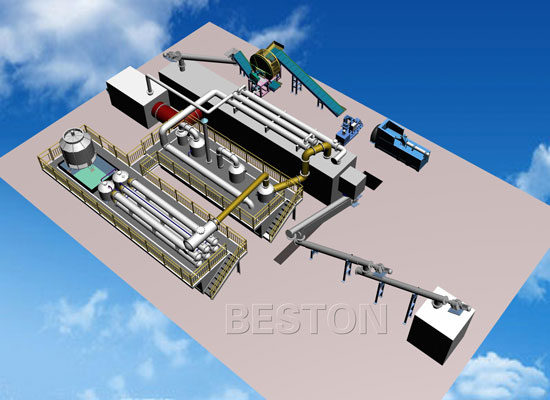

Distinctive egg tray drying lines.

Quality and toughness of the egg trays are significantly reliant on the drying line. The drying lines utilized are block drying and multi-layer drying. Block drying line of small semi-automatic paper egg tray making machine is made of blocks and aides in enhancing the time span of usability of the egg tray. Multi-layer drying line is made of various metal layers. Block drying line is anything but difficult to keep up and has an augmented life since it is made of blocks while the multi-layer drying line involves a little space and has a simple establishment. Contingent upon your inclination one can pick a drying line that best suits the assembling needs.

The essential favored angle of this machine is that it uses misuse materials as its data thusly being profitable as to environment insurance. Its principal unrefined materials include water and waste paper; this reductions the ruinous impact that the waste material could have made to nature. The manual egg tray making machine is definitely not hard to work and profitable in this manner making it easy to keep up and use while receiving the best in return. The machine has a wide operation and can, then again, be used to make shoe supporters, apple trays and distinctive sorts of paper trays by changing the molds. The machine has various financial inclinations like usage of direct wellspring of essentialness and low work. Another money related favorable position is sensibility of the machine and low bolster cost.

The egg tray machine price is assorted depending upon the operation favored viewpoint, producer, and size. While hunting down one, it respects consider the measure of pined for yield, a wellspring of constrain and alternative applications that the machine has isolated from making egg trays. Find more paper egg tray machine manufacturers, and then choose a reliable one. Full customized egg tray making machine is perfect for private use or for a low production of egg trays. In the event that you desire an extended creation, the self-loader egg tray making machine is perfect.