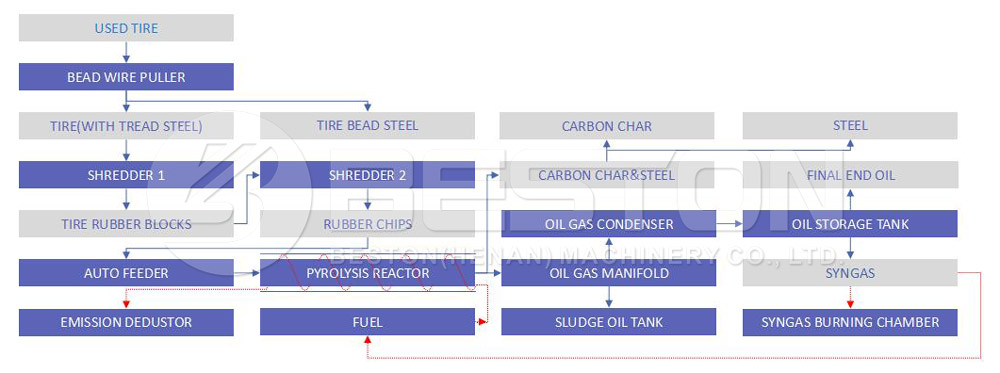

You’ve heard enough about companies investing in pyrolysis plants, and you’ve decided to look at this type of project yourself. You know the numbers need to add up, and you may even be skeptical as to whether or not this venture would end up being profitable for you. You know the pyrolysis system keeps the tires out of landfills. Also, the tyre recycling business will bring you great benefits.

Waste Tyre Pyrolysis Plant Project

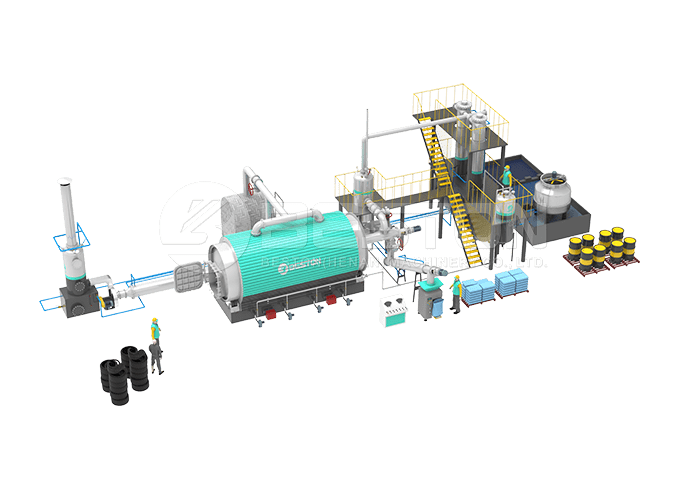

You want to take on this type of recycling effort and know that you’re going to benefit your business as well. You certainly know that there are small batch pyrolysis units, semi-continuous and fully continuous plants for sale on the market. Some investors prefer large pyrolysis plants, while some love the small pyrolysis machine. Just find a suitable one, so these machines are evidently working out for some owners. Will one work for you?

So you need to know how much tire waste do you have to recycle? Have you been recycling the tires in a different way? Also, think about the budget, space, etc. If you have limited tires to recycle, or limited funds, you’re going to need to make an investment in a small pyrolysis machine first. It is more affordable.

Once you do that, you’re going to enjoy the simple fact that the small scale pyrolysis unit actually runs itself in terms of energy costs. And if you get a continuous pyrolysis plant, minimal manpower is required to run the machine anyway. Now that sounds like a winning combination, right?

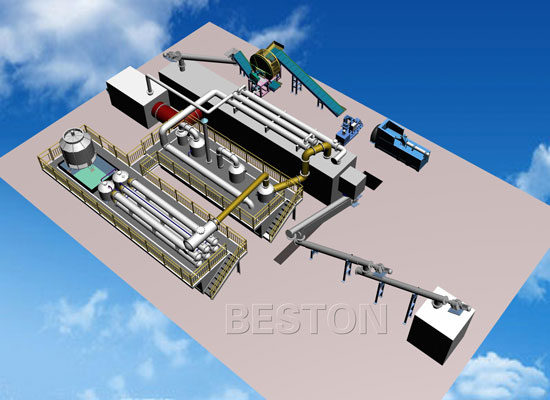

You are definitely thinking that you want to save money on this investment. Yet you want to be sure that you don’t skip over the simple fact that you want a continuous pyrolysis plant, not one that has to be stopped and cleaned in order to keep going. That will give you too much downtime and take up too much manpower. But for example, the capacity of the continuous pyrolysis plant from Beston Machinery will be more than 20 tons. And it is more expensive than the batch pyrolysis plant. Please take all these factors into account.

Pay a little more, but still, look for the best deal. Get a continuous tyre pyrolysis plant that runs 24/7 for you so that you are able to count on it recycling tires continuously, netting you treasure from your trash. That carbon black is going to be able to generate you some profits. You will also make money back from the steel. More details can be found: https://wasterecyclingplant.com/continuous-tyre-pyrolysis-plant/.

Continuous Tyre to Oil Plant to Romania

You’re going to have to think a little harder how you plan to use the pyrolysis oil. That is what will help fuel your plant, but decide what’s best for the rest. Do you want to refine it further into better fuel? Do you have contacts that will allow you to sell the oil to other businesses for a small profit?

You certainly have options, and you want all of your bases covered before you purchase a pyrolysis plant. Once you have one set up at your place of business, it’s all about recycling as many tires as you can, ramping up those profits. It really is a great way to maximize profits for your business, when you think about the fact that you’re also recycling waste vs taking it to the landfill. You can find more information from the related blogs: http://decemberyue.simplesite.com/.