Pyrolysis is a versatile process that converts organic materials into valuable products such as biochar, bio-oil, and syngas through thermal decomposition in the absence of oxygen. While the basic principles of pyrolysis remain the same, the composition and physical characteristics of the feedstock can significantly affect the efficiency of the process and the quality of the by-products. Two common feedstocks in pyrolysis are fruit shells and straw. Both materials offer distinct challenges and opportunities during pyrolysis, making it essential to understand how their properties influence the process.

Material Composition and Structure

The first significant difference between fruit shells and straw lies in their material composition. Fruit shells, such as those from coconuts, almonds, or palm nuts, are dense and have a high lignin content, which contributes to their robustness. This dense structure means that fruit shells require higher temperatures to break down in the specialized equipment, such as coconut charcoal machine, often resulting in a slower process. The high lignin content also tends to produce more stable biochar, which has better carbon retention properties.

Straw, on the other hand, is lighter and more fibrous. It is predominantly composed of cellulose, hemicellulose, and a lower amount of lignin compared to fruit shells. These materials are more susceptible to decomposition at lower temperatures, leading to faster pyrolysis times. The relative lack of lignin in straw often results in a biochar with lower structural stability and carbon content compared to fruit shell biochar. As a result, straw-derived biochar may not offer the same long-term carbon sequestration benefits.

Pyrolysis Temperature and Duration

The pyrolysis of fruit shells generally requires higher temperatures than straw. The dense, tough nature of fruit shells means they take longer to break down into smaller components under heat. This can lead to a more prolonged pyrolysis process, typically requiring temperatures of around 400-600°C. The higher heat helps break down the lignin and cellulose in the shells, leading to a higher yield of biochar with more stable carbon content.

Straw, with its lower lignin content, can decompose at lower temperatures, typically between 300-500°C. Because of its fibrous nature, straw pyrolysis is more efficient in terms of time, requiring less energy to reach the desired pyrolysis temperature. The process is often quicker, with shorter residence times in the straw charcoal machine, making it a more energy-efficient option compared to fruit shells.

Yield of By-products: Biochar, Bio-oil, and Syngas

The differences in feedstock composition between fruit shells and straw also influence the yield and quality of the by-products generated during pyrolysis. In general, fruit shells tend to produce a higher yield of biochar due to their high lignin content. The biochar produced from fruit shells is denser and has a higher carbon content, which makes it more suitable for long-term use as a soil amendment or as a material in industrial applications like carbon filtration.

In contrast, straw pyrolysis tends to yield a higher amount of bio-oil and syngas compared to biochar. The lower carbon content in straw means that more of the organic matter is converted into volatile compounds during pyrolysis. These compounds can be condensed into bio-oil, which has applications as an alternative fuel source. Syngas, primarily composed of hydrogen and carbon monoxide, is also produced in larger quantities when processing straw, making it a good feedstock for energy generation.

The variation in the ratio of biochar, bio-oil, and syngas is an important consideration when selecting feedstocks for pyrolysis machine. If the goal is to maximize biochar production for agricultural or industrial use, fruit shells would be the preferable option. However, if the aim is to generate bio-oil for fuel production or syngas for energy generation, straw would be a better choice due to its higher yield of volatile compounds.

Charcoal Machine Efficiency

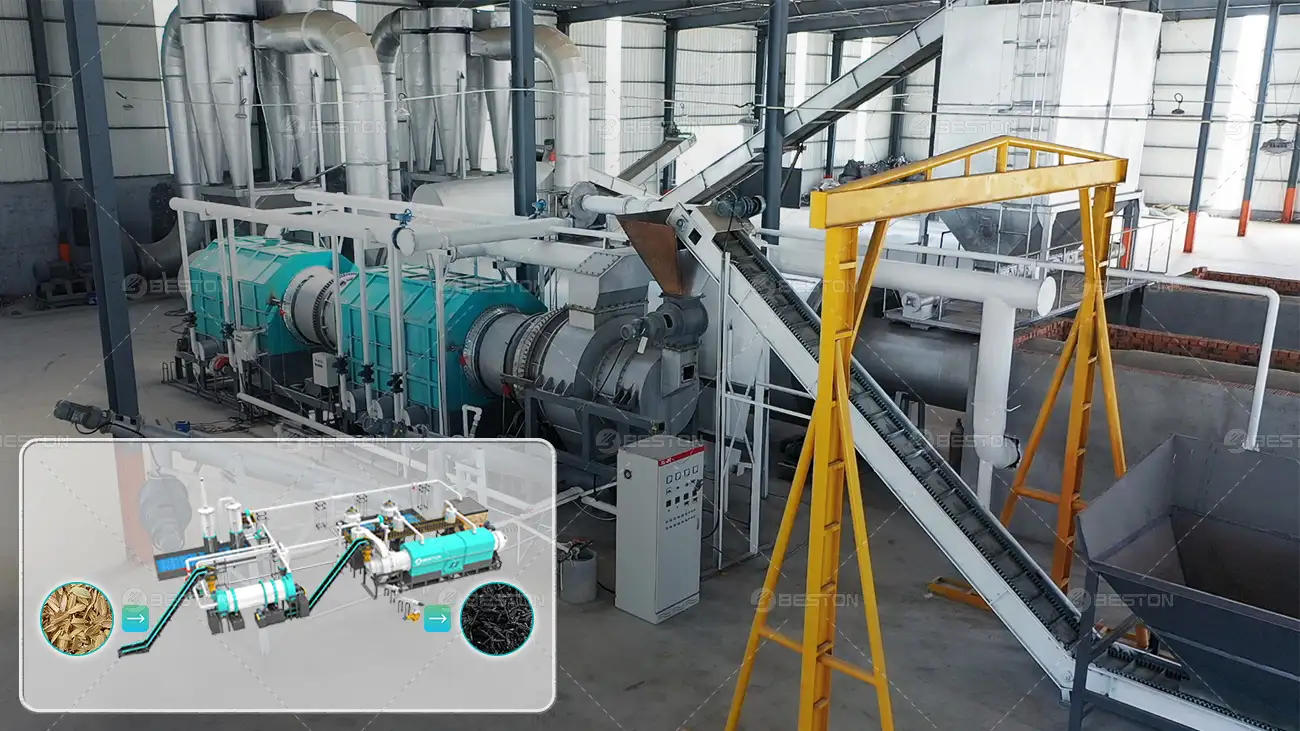

The differences in the pyrolysis process of fruit shells and straw can also affect the efficiency of the charcoal machine used. For fruit shells, which require higher temperatures and longer processing times, the machine needs to be equipped with advanced temperature controls and possibly a more robust heating system to handle the denser feedstock. The slower decomposition process may also require more careful monitoring to prevent overheating or incomplete combustion.

For straw, the quicker pyrolysis process means that the machine can operate at lower temperatures, which might reduce energy consumption. The more fibrous nature of straw may also require different shredding or grinding mechanisms in the charcoal production machine to ensure uniformity of the feedstock and optimize the pyrolysis process. This adaptability in machine design is crucial for achieving maximum efficiency and ensuring consistent product quality.

Environmental Considerations

From an environmental standpoint, the pyrolysis of both fruit shells and straw offers significant benefits compared to open burning or landfilling. However, the environmental footprint of each process can differ based on the feedstock. Fruit shell pyrolysis, with its higher biochar yield, contributes more to carbon sequestration, helping mitigate climate change by storing carbon in the soil. In contrast, straw pyrolysis, with its higher syngas and bio-oil output, can contribute to energy generation, providing a renewable energy source that reduces dependence on fossil fuels.

The environmental impact also depends on the efficiency of the charcoal machine used. Machines that are optimized for energy efficiency and minimal emissions can reduce the overall carbon footprint of the pyrolysis process, regardless of the feedstock. By incorporating modern technologies that recover heat and optimize fuel consumption, both fruit shell and straw pyrolysis can be made more environmentally friendly.