Improper disposal of tires has been proven to pose a negative impact to the environment. This is because used tires have proved to be quite hazardous to the environment given the fact that they usually burn-up without any notice thereby releasing dangerous fumes into the air. And if this continues, the impact will definitely be felt even by generations still to come. That is why recycling old tires is imperative rather than burning them. This can be done using recycling tyre to fuel recycling plant. The plant converts the tires to industrial fuels (final products) such as steel wire, carbon black, tire pyrolysis and hydrocarbon gas as well. With that said, let’s find out the advantages of this Recycling tires into oil pyrolysis plant, the applications as well as the impact of the plant.

Advantages of Tire to Oil Plant

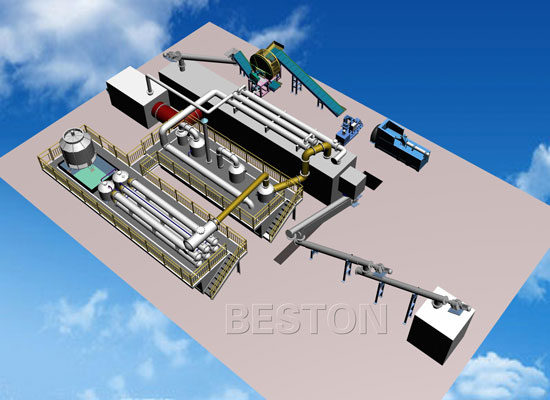

The used tires also referred to as “black pollution” can easily cause fire when not properly disposed. So this Recycling tires into oil pyrolysis plant usually eliminates all the possible problems presented by burning and disposing waste tires by finding a way of putting the tires into proper use. The process of recycling takes place in the absence of oxygen to prevent the tire from burning thereby preventing toxic fumes from being released in the air. In addition, the recycling tires into oil pyrolysis plant is fitted with safety devices and more advanced de-dusting systems that guarantees safety and no pollution during the tire to oil pyrolysis recycling process. The plant also saves energy while protecting the environment thereby proving to be a great thing especially on the modern society.

Applications of the Final Products

The final products produced by tyre oil plant have quite a number of applications. For the carbon black, it can be used both as fuel or for construction of bricks with clay. The tire pyrolysis oil on the other hand can be used within the industrial fuel materials for burning or sold directly. It can also be refined further to produce gasoline or diesel and used in low –speed engines like loading machine, digging machine or road roller, etc. Additionally, the steel wire can be recycled into smelting plant or used re-sale or processing.

Impact of Recycling Tire To Oil Plant

Looking at the hazardous effect old tires have to the environmental surroundings, no doubt the recycling tires into oil pyrolysis plant technology has a great impact to the environment. First, it has eliminated the amount of used tires that are disposed every day thereby preventing air pollution. Secondly, since the final products realized after the process of recycling the tires into oil pyrolysis are not a waste, the plant users are able to make some income by re-using them or even re-selling them. It can therefore be concluded that this plant technology has only brought positive impact to the world and especially to the environment. Beston Machinery is waste tyre recycling plant, which has excellent reputation in international market.

Recycling tires into oil pyrolysis plant is a true game changer hence represents the future of used tire recycling. The advantages of the tyre to fuel recycling plant outweigh its drawbacks keeping in mind the impact it has especially for the young generation and the one still to come. That is why more and more people are adopting this technology every day. Please don’t hesitate to click this link https://TYREPYROLYSISPLANTS.net/.