A pyrolysis plant, one that is either large or small, can produce a couple byproducts that are marketable. It can produce bio oil which can be used to power diesel engines. It will also produce char which can be made into charcoal briquettes. Both of these products can be sold for top dollar, and it is possible to use a wide variety of products that are both chemically based and natural. It is possible to use plastic and tires which are manufactured, or you can use natural products like coconut shells, and a variety of different types of plants, that can produce similar results. The continuous pyrolysis equipment design is probably your best bet if you would like to get excellent results.

Why Are These Popular Today?

Before discussing this particular design, it’s important to realize why so many people are focused on all of this. It has to do with people realizing it is so important to recycle, and in doing so, you can create reusable products. That being said, this look at this continuous waste plastic recycling machine design as it stands today.

How The Pyrolysis Process Works

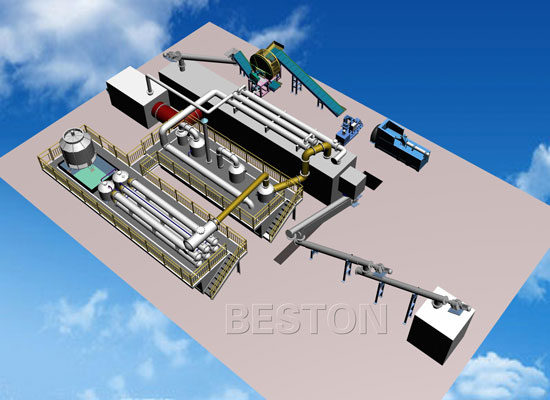

This is a three stage process which involves many secondary steps, all of which work together in order to produce the end products. The first step of the process is acquiring materials that will be processed, and getting them ready for going into the waste plastic and tyre pyrolysis plant. For example, if you are using rubber tires, you must buy a special device that can chip the tires down into very small sizes. This can be done with any of the materials that can be used with a pyrolysis plant, and then it will be ready for production. The second stages to use a conveyor belt to run all of this material into a pyrolysis furnace. This will be a chamber where all of the material will be superheated, but there will not be any oxygen. With the absence of oxygen, combustion cannot occur and therefore a chemical process will happen. This will break everything down into component parts which will include different types of gas, bio oil, and char. The third part of the process is actually taking the bio oil and the char and making the biofuel and charcoal briquettes, respectively. This is how all of them work, with the larger ones being able to produce a substantial amount of product, especially if they have access to a virtually unlimited supply of plastic, tires, or deciduous material that can be processed for this purpose. Inquiry for the free quote of tyre pyrolysis plant price.