In an era where environmental consciousness is paramount, industries are seeking innovative solutions to reduce their ecological footprint. Pulp molding machines have emerged as a sustainable alternative for producing packaging materials, utilizing eco-friendly paper pulp to create a wide range of products. This article explores the workings of pulp molding machines and the benefits of eco-friendly paper pulp molding products, highlighting their role in fostering environmental sustainability and promoting circular economy principles.

Understanding Pulp Molding Machines

Pulp molding machine, also known as pulp molding equipment or pulp molding production lines, are designed to manufacture packaging and other products using recycled paper pulp as the primary raw material. The process involves several key steps: pulping, molding, drying, and finishing. Initially, recycled paper or cardboard is shredded and mixed with water to create a slurry, which is then formed into specific shapes and structures using molds or dies within the pulp molding machine. After molding, the products are dried using heat or air, resulting in sturdy and customizable packaging solutions.

Versatility and Customization

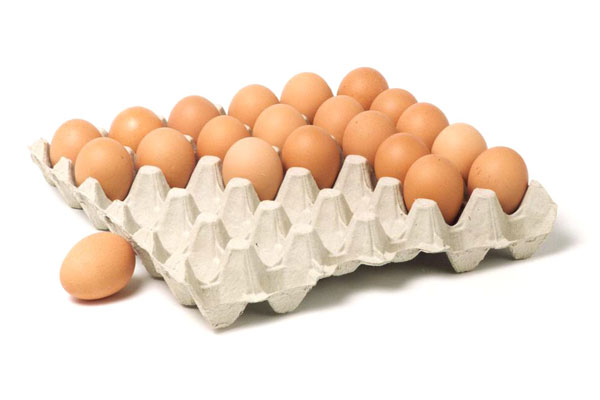

One of the primary advantages of pulp molding machines is their versatility and ability to produce a wide range of products to meet diverse packaging needs. From egg cartons and beverage trays to electronic packaging and protective inserts, pulp molding technology offers endless possibilities for customization. Manufacturers can easily adjust the design, size, and specifications of the products to accommodate various industries and applications, ensuring optimal functionality and protection for packaged goods.

Environmental Benefits

The adoption of paper egg tray making machine for packaging production brings significant environmental benefits. Unlike traditional packaging materials such as plastic, foam, or Styrofoam, which contribute to pollution and resource depletion, eco-friendly paper pulp is derived from recycled paper or agricultural residues, reducing the demand for virgin materials and mitigating waste accumulation. Additionally, paper pulp packaging is biodegradable, compostable, and recyclable, offering a sustainable end-of-life solution that minimizes environmental impact and promotes circularity in the packaging industry.

Resource Efficiency and Waste Reduction

Pulp molding machines promote resource efficiency by utilizing recycled paper and cardboard as feedstock, diverting these materials from landfills and incineration facilities. Moreover, the production process itself is highly efficient, requiring minimal energy and water compared to traditional manufacturing methods. Additionally, pulp molding technology enables the use of byproducts and waste streams from other industries, such as agricultural residues or sugarcane bagasse, further reducing waste generation and maximizing resource utilization.

Consumer Preference and Brand Image

In today’s market, consumers are increasingly prioritizing sustainability and seeking eco-friendly alternatives in their purchasing decisions. Eco-friendly paper pulp molding products resonate with environmentally conscious consumers due to their renewable nature, biodegradability, and low environmental footprint. Brands that adopt pulp molding packaging not only appeal to environmentally aware consumers but also enhance their brand image as responsible stewards of the environment, fostering loyalty and trust among customers. See egg carton machine here.

Challenges and Considerations

While pulp molding machines offer numerous environmental and economic benefits, certain challenges and considerations must be addressed to maximize their potential. One challenge is the need for investment in research and development to enhance the efficiency, speed, and automation of pulp molding processes, making them more competitive with conventional packaging materials. Additionally, overcoming logistical constraints related to raw material sourcing, transportation, and supply chain management is crucial for scaling up pulp molding operations and reaching broader markets.

Conclusion

Pulp molding machines and eco-friendly paper pulp molding products represent a paradigm shift in the packaging industry, offering sustainable alternatives to traditional packaging materials and practices. By harnessing recycled paper pulp and adopting circular economy principles, these technologies contribute to resource conservation, waste reduction, and environmental stewardship. However, realizing the full potential of pulp molding requires collaboration among policymakers, industry stakeholders, and consumers to address technological, logistical, and market challenges. With concerted efforts and continued innovation, pulp molding machines have the power to revolutionize packaging practices and pave the way towards a more sustainable future. Get a high productivity automatic egg tray making machine here.